Current Positions:Home>>Equipment products

-

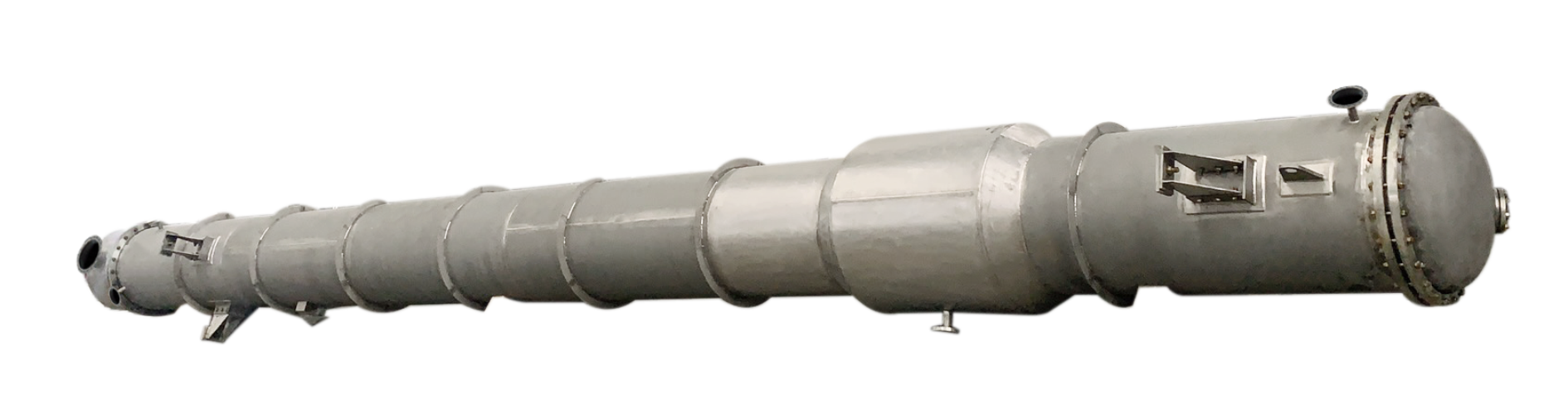

The secondary steam generated by itself is compressed and heated by a compressor to increase its enthalpy, and its latent heat is fully utilized as a heat source to heat the feed liquid in the evaporator of the system again, so as to realize concentration, desalination and COD removal. Except that the system needs to be heated and preheated in the startup stage, other auxiliary heating is basically not needed or rarely needed in the operation process; the condensed water generated after the secondary steam is heat transferred can.

The secondary steam generated by itself is compressed and heated by a compressor to increase its enthalpy, and its latent heat is fully utilized as a heat source to heat the feed liquid in the evaporator of the system again, so as to realize concentration, desalination and COD removal. Except that the system needs to be heated and preheated in the startup stage, other auxiliary heating is basically not needed or rarely needed in the operation process; the condensed water generated after the secondary steam is heat transferred can. -

Multi-effect evaporation is a traditional energy-saving evaporation technology, which reduces the energy consumption of the system by using the pre-effect heat energy. The energy consumption of the multi-effect evaporation system is mainly steam, especially suitable for the operation environment where steam is sufficient and power is short. It is widely used in the evaporation, concentration, crystallization and wastewater treatment of many industries such as medicine, food, chemical industry, printing and dyeing, etc.

Multi-effect evaporation is a traditional energy-saving evaporation technology, which reduces the energy consumption of the system by using the pre-effect heat energy. The energy consumption of the multi-effect evaporation system is mainly steam, especially suitable for the operation environment where steam is sufficient and power is short. It is widely used in the evaporation, concentration, crystallization and wastewater treatment of many industries such as medicine, food, chemical industry, printing and dyeing, etc. -

In the oxygen-free state, the system carries out cracking carbonization treatment of production wastes by controlling environmental load, and reduces pollutants harmlessly.

In the oxygen-free state, the system carries out cracking carbonization treatment of production wastes by controlling environmental load, and reduces pollutants harmlessly. -

Advantage products include CZ standard chemical process, ZWII axial flow pump, HW mixed flow pump, YT liquid pump, ITM magnetic pump, CL discharge pump equipment, corrosion resistance, good wear resistance, reliable sealing performance.

Advantage products include CZ standard chemical process, ZWII axial flow pump, HW mixed flow pump, YT liquid pump, ITM magnetic pump, CL discharge pump equipment, corrosion resistance, good wear resistance, reliable sealing performance.