-

Through wet process, valuable metals such as nickel, cobalt, manganese, lithium, and by-products such as sodium sulfate and ammonium sulfate in the black powder of ternary batteries and lithium iron phosphate batteries can be recovered efficiently. This process has the advantages of strong material adaptability, high metal recovery, high purity, high quality and stability, low energy consumption and long-term continuous and stable operation. Among them, the process of recycling battery grade iron phosphate products from phosphorous residue is at the leading level in the industry.

Through wet process, valuable metals such as nickel, cobalt, manganese, lithium, and by-products such as sodium sulfate and ammonium sulfate in the black powder of ternary batteries and lithium iron phosphate batteries can be recovered efficiently. This process has the advantages of strong material adaptability, high metal recovery, high purity, high quality and stability, low energy consumption and long-term continuous and stable operation. Among them, the process of recycling battery grade iron phosphate products from phosphorous residue is at the leading level in the industry. -

It is mainly aimed at the disposal of washing water and mother liquor in the production process of ternary precursor and ferric phosphate precursor, as well as the treatment of high salt wastewater such as fluoride waste gas absorption solution in electrolyte. This process has the advantages of low comprehensive treatment cost and high impurity removal rate, and the obtained by-products such as sodium sulfate, ammonium sulfate, monoammonium phosphate and ammonium chloride are of high quality and can produce a large profit.

It is mainly aimed at the disposal of washing water and mother liquor in the production process of ternary precursor and ferric phosphate precursor, as well as the treatment of high salt wastewater such as fluoride waste gas absorption solution in electrolyte. This process has the advantages of low comprehensive treatment cost and high impurity removal rate, and the obtained by-products such as sodium sulfate, ammonium sulfate, monoammonium phosphate and ammonium chloride are of high quality and can produce a large profit. -

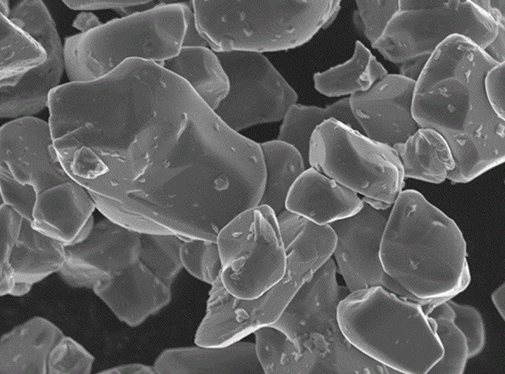

It is mainly aimed at evaporation, concentration, crystallization, drying and other processes during the production of lithium battery raw materials, including nickel sulfate, cobalt sulfate, manganese sulfate, lithium carbonate, lithium hydroxide and other lithium battery raw materials production, with advantages of energy saving, stability, less lithium loss, uniform crystal particles and so on. In particular, it has a unique technology in the concentration and extraction process of lithium carbonate, with high yield and good quality.

It is mainly aimed at evaporation, concentration, crystallization, drying and other processes during the production of lithium battery raw materials, including nickel sulfate, cobalt sulfate, manganese sulfate, lithium carbonate, lithium hydroxide and other lithium battery raw materials production, with advantages of energy saving, stability, less lithium loss, uniform crystal particles and so on. In particular, it has a unique technology in the concentration and extraction process of lithium carbonate, with high yield and good quality. -

In the process of electrolytic aluminum production, the lithium extraction technology of electrolyte waste liquid and overhaul slag can recycle all the valuable resources such as lithium, fluorine and aluminum in the waste slag of electrolytic aluminum containing lithium into treasure with advantages of high product quality, high lithium element recovery and low production cost. This process can not only eliminate the impact of aluminum slag on the environment, but also help to relieve the pressure of lithium resource demand, solve the problem restricting the development of electrolytic aluminum industry, and promote the sustainable and healthy development of electrolytic aluminum industry, fluorine chemical industry and new energy industry.

In the process of electrolytic aluminum production, the lithium extraction technology of electrolyte waste liquid and overhaul slag can recycle all the valuable resources such as lithium, fluorine and aluminum in the waste slag of electrolytic aluminum containing lithium into treasure with advantages of high product quality, high lithium element recovery and low production cost. This process can not only eliminate the impact of aluminum slag on the environment, but also help to relieve the pressure of lithium resource demand, solve the problem restricting the development of electrolytic aluminum industry, and promote the sustainable and healthy development of electrolytic aluminum industry, fluorine chemical industry and new energy industry. -

It is a management system integrating intelligent operation management platform, intelligent safety management platform, production operation management platform, intelligent inspection robot, intelligent algorithm and digital factory. It improves enterprise management efficiency through equipment inspection, equipment maintenance and repair, hidden danger reporting/warning, spare parts management and other aspects. The whole process of source control, process supervision, end treatment, to protect the safety of enterprise production, and help enterprises to start the first shot of "smart environmental protection".

It is a management system integrating intelligent operation management platform, intelligent safety management platform, production operation management platform, intelligent inspection robot, intelligent algorithm and digital factory. It improves enterprise management efficiency through equipment inspection, equipment maintenance and repair, hidden danger reporting/warning, spare parts management and other aspects. The whole process of source control, process supervision, end treatment, to protect the safety of enterprise production, and help enterprises to start the first shot of "smart environmental protection".